Channel

Mechanical Properties

Channels are steel beams that feature a unique "C" shaped profile, with a web and flanges that provide structural efficiency and versatility. They offer excellent mechanical properties such as high tensile strength and good bending resistance, making them suitable for both load-bearing applications and as part of the non-load bearing structures like frames and rails. The shape of the channel section enhances its ability to resist bending in one direction, making it an ideal choice for applications where directional strength is important.

Bendability

The bendability of Channels depends on the specific steel grade and thickness of the material. Generally, they offer a moderate level of bendability, allowing them to be used in applications requiring curved forms or angles. This flexibility makes Channels suitable for various architectural and structural designs where complex shapes are needed.

Dimensional Tolerance

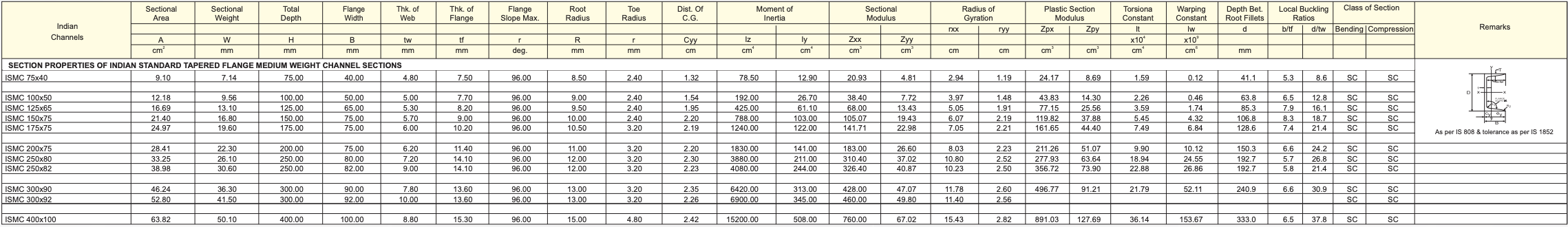

Channels are manufactured with precise dimensional tolerances, ensuring consistency in size, shape, and straightness. These tolerances are critical for applications where precise alignments and fittings are necessary. Dimensional tolerances for Channels include the height and width of the web and flanges, as well as the thickness of the material, ensuring that each section performs as expected in its designated application.

Corrosion Resistant

Like other steel profiles, Channels can be treated to enhance their corrosion resistance. Common treatments include galvanizing, which involves coating the steel with a protective layer of zinc, and painting or applying other protective coatings. These treatments are essential for extending the lifespan of Channels used in outdoor or corrosive environments, reducing maintenance costs, and ensuring the longevity of the structures they support.

Where do you need it?

Channels are versatile and find applications across a broad spectrum of construction and engineering projects, including:

- Building Frameworks: Used as part of the structural framework in buildings, providing support for floors, walls, and ceilings.

- Support Systems: Serving as supports for mechanical, electrical, and plumbing systems within both residential and commercial buildings.

- Industrial Applications: In manufacturing facilities and warehouses, Channels are used as part of conveyor systems, equipment frameworks, and storage racks.

- Architectural Features: Employed in architectural designs for creating aesthetic elements such as trim, facades, and frame structures.

- Infrastructure Projects: Utilized in the construction of bridges, signposts, and rail systems, where their strength and flexibility are valuable assets.

- Vehicle Construction: In the automotive and shipbuilding industries, Channels are used in the framework of vehicles and vessels for their structural integrity and lightweight properties.